I hope you all had a wonderful holiday. I was very excited to process so many orders through the Christmas season. New orders mean new customers who help contribute to our wonderful community of Inspiration users here in the Craft Room. So with new customers comes an array of new questions. While this may seem like a beginner question to some, it’s also a great question to remind our seasoned Inspiration users of as well.

Why are some of the pieces to my design not cut all the way through?

Mitch K. Sacramento, CA

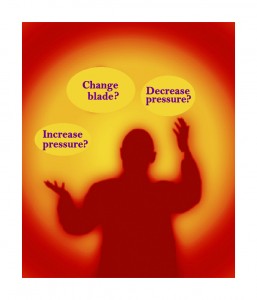

The first thing that you will want to try is changing out your blade. It’s very easy to forget the last time that the blade was changed and what materials the blade has cut. If you’re cutting through heavier paper on a consistent basis and then try to cut vinyl or vellum, the blade might not be able to handle cutting through such delicate materials. As a result you’ll find that your cuts have a more serrated look and that certain parts of the image aren’t cut at all. Increasing the pressure may help, but if you’re working with more delicate materials this really isn’t an option as working with a higher pressure can cause the paper or vinyl to bunch up and tear. All papers are going to be different, who knew?! I always thought paper was paper. However, there are not only a hundred different brands out there, but they come in several different thicknesses and texture too which will make a difference as to the settings that you need to use. If you’re not using enough pressure your images will not cut out completely either. Try increasing the pressure in increments of 2 so that you’re making a gradual increase instead of increasing and decreasing in larger increments. Often times I find that when I visit with people having pressure issues they will increase the pressure to extreme numbers and when the cuts don’t look like they should, they’ll begin decreasing the pressure in extreme increments. Remember there’s a wide range of numbers in between that can give you amazing results if you take the time to adjust and work with the settings.

If you haven’t already, make sure you check out this blog and video on determining the blade length and pressure for any material you are cutting. This is a MUST SEE for any beginner and really ANY Inspiration user. h

Tatum I would like to add that sometimes if the blade isn’t cutting and it is tearing you need to take it out and see if there is paper caught on it and clean it up. A pair of needle nose tweezers very gently inside will pull out the paper that gets lodged inside, but do be careful when retrieving it. I also found out, when trying to make those pretty card Christine had, I got some paper that had a texture on it (not Bazzil) well they were textured on both sides and would not lay on the matt, I watched it as it was cutting and it just pushed the paper up and down, kinda like watching the rolling see. Needless to say I returned the paper and next time I want textured paper to use with my Pazzle it will be the Bazzil). I know it was the paper because i had changed pressure, mats etc. So remember it could be the paper or a combination of all. Have a Happy New Year to you all at Pazzles.

Gloria, good suggestion! There’s an awful lot to be said when it comes to paper. Some papers are just made differently and that makes a huge difference in the way it will cut with your Inspiration. We had some paper here in our office that was from a paper pack that I just couldn’t get good clean cuts with. It looked and felt like Worldwin paper, but it definitely did not cut the same. I think sometimes the core of papers are softer than the outer layer and that’s why different papers need different settings even if they feel the same.

I did a test recently. I tried to cut a design I had successfully cut before with a different PI machine. Same paper, but after a few cuts with the new machine I noticed the paper started tearing. In this case it was not the paper. I also tried different blade lengths and pressures and a different mat. I don’t understand why the paper started to tear all of a sudden. I took the same paper and cut it on my CE and it cut just fine. I personally don’t understand how humidity or whatever affects cutting on the PI, but does not affect the cuts on the CE – they are both die-cut machines and located in the same room.

Humidity has an incredible effect on paper. I have experienced this first hand while traveling across the country doing shows. I have even walked into the show hall in the morning to see every vendor’s papers drooping due to humidity. Once the air conditioning went on the paper literally perked up! The paper absorbs the moisture which makes is softer. I am sure Klo has also experienced how variances in humidity will change the pressure needed to cut paper.